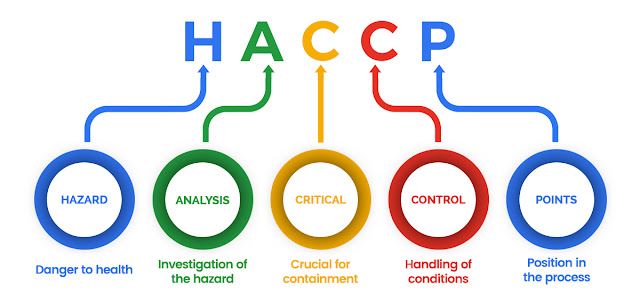

HACCP- Hazard Analysis & Critical Control Point

My

current blog is a must read for all those who are associated with Food

production, kitchen and also for those who work in kitchen.

As each

sector is experiencing heavy growth and development, Kitchen is not an

exception either. The fundamentals of kitchen have excelled and the quality of

kitchen has been enhanced as well.

The

detail regarding this topic can be read more appropriately in Principles of Food Production Operations.

Hazard

Analysis & Critical Control Point is a system adopted by Codex Alimentarius

Commission. It is

conceptualized with a set of principles that actually is the framework of this

systematic system, based on science. It identifies specific hazards, evaluates

and provides measures for their control to ensure the safety of the food. Thus

actually it is a tool that assesses hazards and thereby establishes control

systems. It has mushroomed to such a level, that it has become the need of the

hour in food sector operations.

HACCP is

concerned right from the purchase of the food material till the final

consumption of the food material. Associated with multiple benefits, it has

strengthen the assurance regarding the quality of food safety management

system, and also aided to reduce the food cost by controlling the wastage due

to microbial infestation

The

HACCP system is based on seven principles mentioned below:

Principle 1: Conduct a hazard analysis.

Principle 2: Determine the Critical Control Points (CCPs).

Principle 3: Establish critical limits.

Principle 4: Establish a system to monitor control of the

CCP.

Principle 5: Establish the corrective action to be taken

when monitoring indicates that a particular CCP is not under control.

Principle 6: Establish procedures for verification to

confirm that the HACCP system is working effectively.

Principle 7: Establish documentation concerning all

procedures and records appropriate to these principles and their application.

General Guidelines

Few

general guidelines associated with HACCP under certain actions are as such:

·

Cleaning and sanitizing food contact surfaces

Ø

The

food contact surfaces such as sinks, tables, equipments, thermometers, and

utensils must be washed before each use, between uses when dealing with

different types of raw ingredients like fish, meat, poultry or vegetable etc.;

and between uses when dealing with or preparing ready-to-eat foods and raw

animal foods; and whenever the contamination occurs or is suspected.

Ø

All

food contact surfaces must be washed with detergent solution, rinsed with clean

water and sanitized with sanitizing solution and then after allowed to dry

properly.

Ø

When

using 3-compartment sink units, first sink is used for washing with detergent

solution at or above 43oC, second sink for rinsing with clean water

and third sink for sanitizing with a sanitizing solution in hot water at or

above 77oC for about 30 seconds.

·

Controlling time temperature

during preparation

Ø

The

ingredients to be used in cold foods (sandwiches, or salads, etc.) should be

pre-chilled to the temperature at around 5oC or below.

Ø

The

food should be prepared closet to the serving time of the food.

Ø

When

the potentially hazardous food is not to be served immediately after cooking,

it should be quickly chilled.

Ø

The

cooked food should never be left at room temperature for more than 30 minutes

or around, but it should be refrigerated.

·

Cooking potentially Hazardous

Foods

Ø

If

a combination of meat product is to be used in a recipe, then cook the food to

the highest required temperature.

Ø

The

following temperature is the desired temperature for cooking:

§

63oC

for 15 seconds for seafood, beef, pork or eggs

§

69oC

for 15 seconds for grinded (beef, pork or fish) products, fish nuggets or

sticks, cubed steaks

§

74oC

for 15 seconds for poultry, stuffed fish, pork, beef or stuffed pasta

§

58oC

for 15 seconds for fresh, frozen, or canned fruits or vegetables. It can either

be held on steam table or kept in a hot box.

·

Personal Hygiene

Ø

One

has to be in good health, properly dressed in uniform, hygienically clean while

working in kitchen. Hands must be washed regularly at regular and appropriate times.

Ø

Nails

must be trimmed properly, no jewellery wearing even by female staff, and hairs

must be restrained by wearing chef cap or other restraints.

Ø

The

food should always be tasted with a spoon and this spoon should be reused only

after proper washing.

Ø

The

eating, drinking, consumption of tobacco should be restricted in a designated

area only where the contamination of food or food surface area may not take

place.

·

Transporting Food to remote sites

(satellite kitchens)

Ø

Frozen

food must always be kept frozen during transportation.

Ø

The

temperature of potentially hazardous foods must be maintained at 5oC

or below and cooked foods transported hot must be at 58oC. This

temperature must be maintained in food carrier as well.

Ø

The

food carrier must be cleaned thoroughly, washed, rinsed and sanitized properly.

The food carrier should have suitable containers with proper section to avoid

mixing of food during transportation, it should be leakage proof, easy to clean

and also approved for holding food.

·

Using Utensils while handling ready-to-eat foods

Ø

The

handling of ready-to-eat foods should never be bare handed except washing of

fruits and vegetables.

Ø

The

use of single-use gloves, deli tissue, foil wrap, tongs, ladles, spoons must be

incorporated while dealing with ready-to-eat foods.

Ø

The

hands should be washed properly after every task like before beginning a new

task, before beginning food preparation, after touching unclean utensils; and

after being interrupted such as answering phone calls, when being in operations

of cooking.

·

Limiting Bacterial growth in Potentially Hazardous Foods by Time

Ø

Establishing

written procedures and codes for identifying particular foods for which time

rather than temperature will be used to control bacterial growth, and procedures

followed when food is kept in danger zone for more than 4 hours.

Ø

The

raw potentially hazardous food should be cooked within 4 hours past the point

when the food is removed from temperature control.

Ø

Do

not mix the different batches of food together in the same container and in

case if they are mixed they should be cooked or served or discarded using the

time of the food in the first batch in the container.

·

Washing fruits and Vegetables

Ø

All

the raw fruits and vegetables should be thoroughly washed before combining it

with other ingredients. The washing of unpeeled fruits and vegetables to be

served must be done. The fresh produce must be washed under cold running water

or by permitted chemicals that comply with 2001 FDA Food Code.

Ø

The

fruits with firm surface must be scrubbed with brush meant for the same

purpose. The damaged or bruised areas must be removed, if any.

Ø

The

fresh-cut items must be labeled and marked with date and refrigerated.

Ø

The

service of raw seed sprouts should be avoided in preschool-age children.

·

Washing Hands

Ø

A

separate hand washing sink should be used for hand washing purpose. The sink

for food preparation, utility and dishwashing should not be used for hand

washing.

Ø

The

provision for warm running water, soap and means to dry the hand should be

provided.

Ø

The

hand should be washed at regular interval like before starting any task in food

area, during cooking, after using

toilets, sneezing, coughing etc.; after touching hairs, body or face, after

handling raw materials like meat, poultry etc.; after touching dirty dishes or

equipments, whenever anyone feels like his/her hands are contaminated and so

on.

Ø

The

hand should be washed using following procedures like washing hand and forearms

with running water at 38oC and with soap, hands should be scrubbed properly for

at least 15-20 seconds and then rinsed with water for 5-10 seconds.

Ø

Using

of hand sanitizer after hands are washed and dried properly.

All the

above mentioned guidelines must be complied with according to State or local

requirements that are based on the 2001

FDA Food Code.

Photographs used are from google 1.

Thank you readers!!

Nice sir

ReplyDeleteControlling time , temperature during preparation was very helpful. 🌹

ReplyDeleteIts very necessary for our daily life routine and thanks for elp us every time

ReplyDeleteRegard sahil wadhwa

👌Excellent Sir !

ReplyDeleteVery good sir... Excellent every onr should read it... ThoseTwhoTdont knowkabout food and food temperature good going👍👍👍👍✌️✌️✌️

ReplyDeleteYogesh,well done and most of the important points are covered by you in brief ...Kudos

ReplyDeleteGreat sir👍

ReplyDeleteReally informative and essential in our day to day life.

ReplyDeleteGreat work sir

ReplyDeleteReally informative and essential in our day to day life.

ReplyDeleteGreat one sir!!!

ReplyDeleteSir really informative and essential in our day to day life ..and one of the best article on HACCP

ReplyDeletenice work sir

ReplyDeletegood sir

ReplyDeleteperfect work👌👍👍👍

ReplyDeleteGreat one Sir.

ReplyDeleteGreat Sir

ReplyDelete